Bale Grazing Wastage Estimation

One extended season grazing option that has raised high interest is bale grazing or grazing bales in-field, rather than in a dry-lot. In articles in the Cattlemen magazine, Greener Pastures Grazing Management estimates that bale grazing costs them 13.2 cents/head/day (average yardage in Alberta is around 70 cents/head/day). They also value every day of bale grazing purchased feed with dry cows as 30 cents/head/day of ‘fertilizer’.

Dennis Lastiwka from AAFC has found that in every 1400 lb alfalfa bale there are about 43 lbs of N and 7 lbs of P205. Dr. Jeff Schoenau from the University of Saskatchewan has found with in-field feeding about 36% of urine nitrogen is captured as inorganic N in the soil. When comparing the capture of manure nutrients they had 30 – 45% recovery of added N and 21-32% of added P with in-field feeding and 5 – 9% recovery of added N and 3 – 5% of added P when spreading manure, with the majority of these losses coming in the feed pens.

There are many variations to how producers are setting up their bale grazing systems. On the intensive end, bales are placed close together to maximize the nutrient deposition benefits and cover the field as evenly as possible; typically this would have bales about 40 feet apart, with about 25 bales/acre. The bales are grazed using electric fencing and typically cattle are given 3 – 5 days of feed at a time. This is the method of bale grazing used in the previous LARA studies.

A less intensive method of bale grazing is to use a hayfield and graze the bales as they are placed by the baler. The bale density in this situation is much lower (2 – 4 bales/acre) and grazing management is also less intense; cattle may have access to a few weeks of feed at one time. In this type of system producers have been experimenting with leaving twine on the bales to help reduce feed waste and to save the labour of twine removal. This is similar to the method used in this trial.

The one question around bale grazing is how much feed is being left behind? Does the amount and cost of waste offset any cost reduction and nutrient benefits?

Methods

Wastage was measured on the same farm using the same cow herd for five winters. Some changes were made to the system during the trial but in general the following methods were used. Each fall tarps were placed in the field with a flag in the centre of each tarp. After snowfall, the bales were weighed and placed on top of the flag. The cattle grazed the bales during the winter, usually January and February. After the snow melted in the spring, residue was collected from the tarps and weighed, before residue us collected the large piles of manure are removed. Samples were taken back to the lab to be dried and sorted in order to estimate the amount of hay versus manure in the residue. Wastage estimates were calculated from these samples.

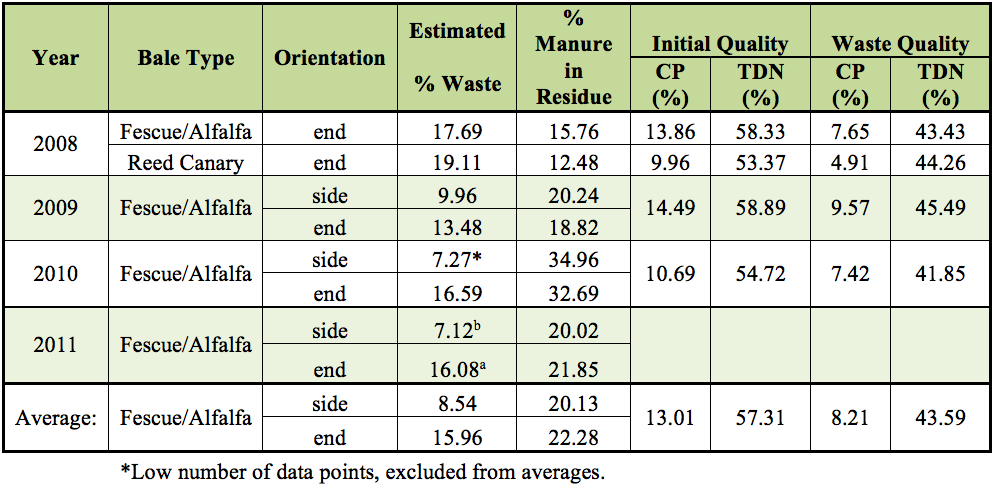

Estimated Waste

The four year average for wastage for end-placed bales is just under 16% (Table 1). The Telliers have commented that this amount of waste seems reasonable for their operation, especially considering that the system is

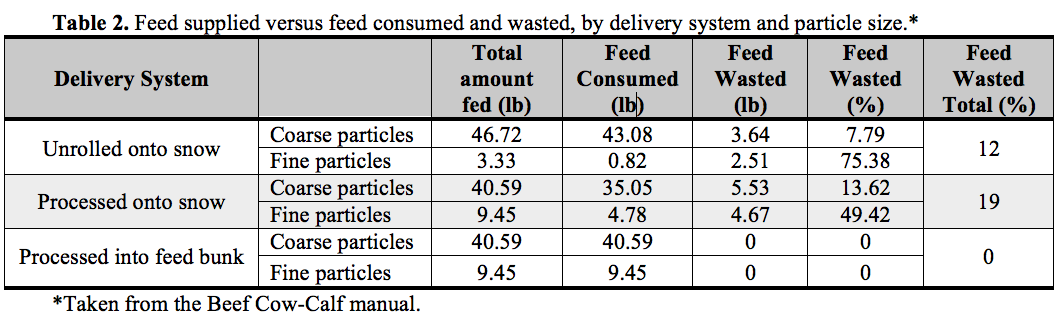

working really well for them and there is noticeable improvement in forage production in the following years. This amount of waste also seems reasonable when compared to previous research done by Barry Yaremcio (Alberta Agriculture) who found that there was 19% waste for bales processed on snow and about 12% for bales unrolled on the snow (Table 2).

There seems to be a reduction in waste when bales are placed on their sides rather than on end. While this was the general trend, the winter of 2011-12 showed statistically significant less waste from side-placed bales than end-placed bales (7% compared to 16%) for the first time.

Table 1. Bale Grazing Wastage Data

Feed Quality

Barry’s study comparing bale processing to unrolling also found that feed quality was lost in the wasted feed, with a much higher proportion of fine particles being lost than coarse particles (Table 2). In the LARA trial, feed samples have shown that the quality of the wasted feed is lower than the initial feed test from the bale. This could indicate that it is the lower quality feed is being wasted, although weathering could also be contributing to quality losses.

Table 2. Feed supplied versus feed consumed and wasted, by delivery system and particle size.

Limited Access

One difference between the Tellier system and other bale grazing systems is the limited access the cow herd has to the bales. Each day the cattle are let into the bales around 9:00 am and then chased out when the kids come home from school around 4:00 pm using stock dogs and snowmobiles.

On the really cold days the cattle were left in the bales overnight or for a few days until the weather changed. This limited access management system is having an unmeasured impact on the amount of waste produced. In other systems the amount of waste may vary depending on management and feed lost to bedding and fouling.

Weather

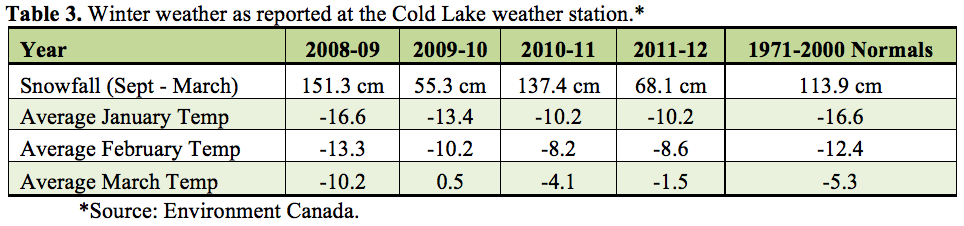

This trial has now been conducted over four winters (Table 3) and weather does seem to have some impact on waste. The winter with the highest snowfall (2008-09) had the highest amount of waste.

Table 3. Winter weather as reported at the Cold Lake weather station

% Manure in Residue

Once samples are brought back to the lab they are weighed, dried, re-weighed and then sorted into residual hay and manure. The average amount of manure in the residue samples has been about 20%, meaning that about 20% of what looks like wasted feed in the field is actually manure (this is shown as % manure in residue in the data table and excludes the large lumps of manure you can see).

Nutrient Benefit

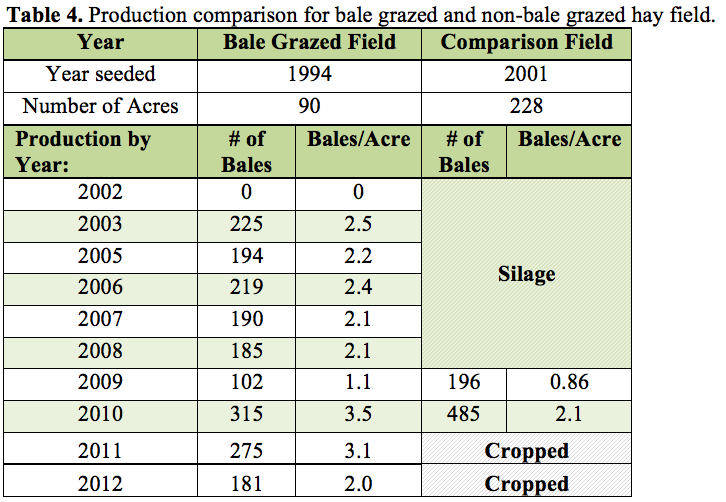

While this trial is mainly looking at waste, a comparison field and visual assessments have been used to try and track some of the nutrient benefits of bale grazing (Table 4). After the first winter of bale grazing the Telliers decided they could increase their bale density to increase the nutrient coverage in their field. In the winter of 2010-2011, the project switched fields to an old pasture where 800 bales were grazed by 500 cows for 57 days. The Telliers commented on how patchy the pasture looked that summer, with taller, thicker, darker green grass around where the bales were placed. This has also been noticeable in other LARA trials and bale grazing tours. Directly under where the bale was placed, residue may remain for more than one year moving out from the bale the grass is much thicker and a darker green. There is some concern about this remaining residue, however the Telliers found they were still able to hay with these residue patches in the field. If there are really thick patches that last for multiple years, bales may be too close together so that residue is overlapping too much.

Table 4. Production comparison for bale grazed and non-bale grazed hay field.

Indicator Bales

In 2008-09 a mixture of fescue-alfalfa and reed canary bales were used. The reed canary bales left more waste, were not preferred and took longer to break down in the field. For the past two winters a few reed canary bales were placed in the field as indicators of when the bales were running out. The cattle would only switch to the reed canary when they were out of the preferred fescue-alfalfa hay. Other systems use straw as the indicator bales.

Twine

The first winter sisal twine was used so that twine could be left on the bales. However, it was found that the sisal didn’t break down fast enough to allow for haying the next summer and twine had to be picked from the field instead. The last two winters plastic baler twine was used, left on the bales and then picked in the spring, but this is both time consuming and messy. For the past two years the twine was cut off the bales in the fall.

Animal Management

The Telliers and other bale grazers have also commented that bale grazing can be hard on the older cows and heifers. Some animals will need to be pulled from the herd, particularly in the first few years of trying a new system.

Future

A fifth year of data was collected in the winter of 2012-2013 using the same pasture and 865 bales of hay, however due to some problems with this data it was not reported. While this trial has now been completed, some additional questions that could be answered with more tarps are:

- Is there a difference in the amount of waste when the twine is removed in the fall?

- What is the interaction between twine and bale placement (ie. twine left on, bale on side versus twine removed, bale on side versus twine left on, bale on end and twine removed, bale on end)?

- Could net wrap work in this system and what impact would it have on waste?

- What is the difference in waste between the Tellier system and a system managed without limited access and a system managed by electric fence?

Summary

What we have learned:

- Bale grazing (in this system with limited access) seems to have a reasonable amount of waste when compared to other in-field winter feeding systems (processing bales, unrolling on snow).

- There seems to be less waste from side placed bales than from end placed bales.

- Bale grazing can improve forage production in the fields where the grazing occurs.

- Remove twin in the fall.

To read more about Extended Grazing, click here.